C Series Temperature Controller

Overview

C Series Temperature Controllers — High-Precision PID & Programmable Control

The C Series Temperature Controllers are ARICO’s flagship models designed for applications requiring high-precision PID control, programmable temperature profiles, and industrial communication integration.

Compared with the A Series—intended for general heating-point control—the C Series offers advanced capabilities including PID + Self-Tuning, dual heating/cooling outputs, 16-step program control, multiple input/output options, and full Modbus RTU / ASCII communication, making it ideal for automated and precision-controlled industrial processes.

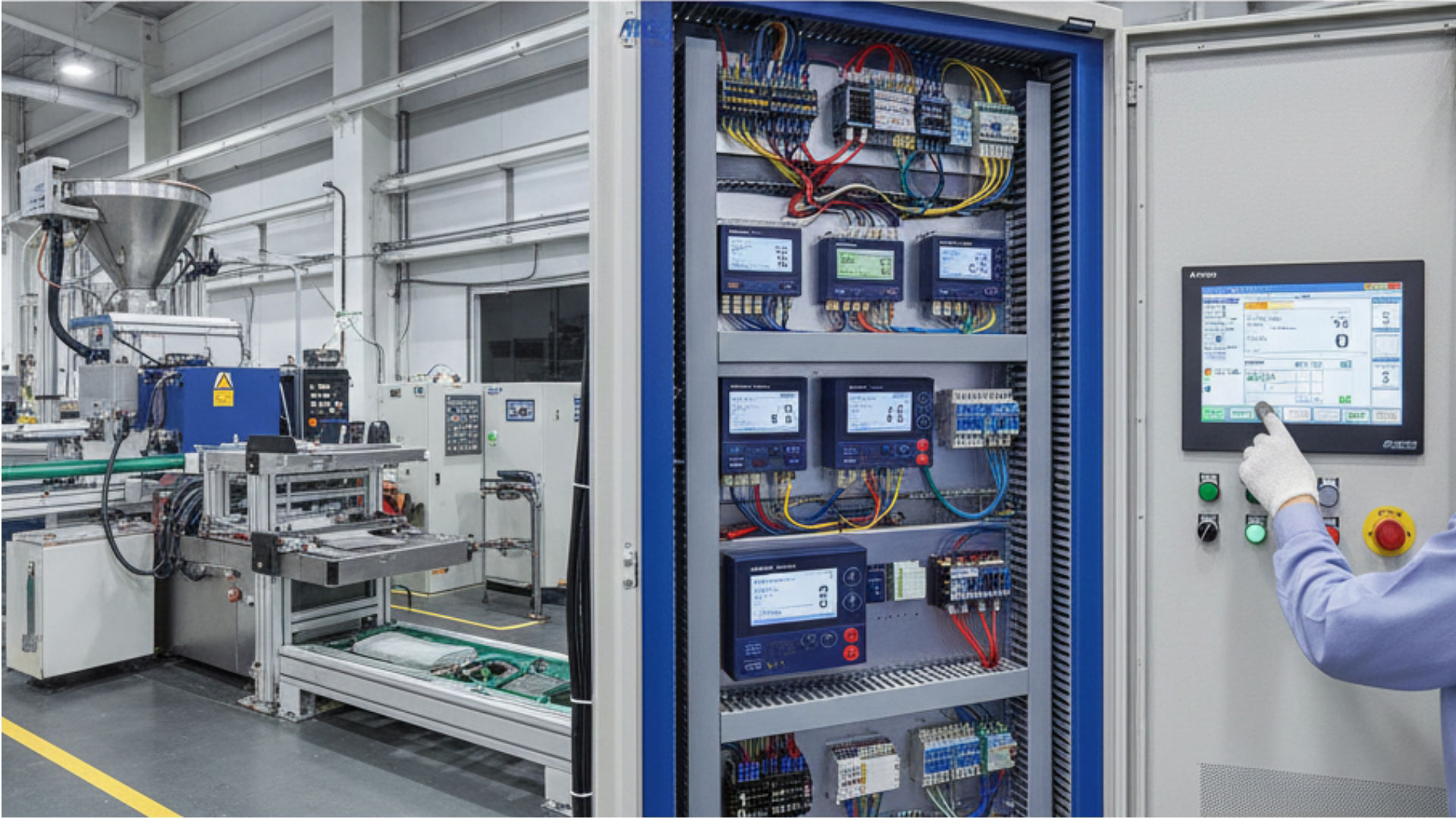

Since its establishment in 1987, ARICO has dedicated many years to temperature and industrial controller development., The C Series for use in injection molding, extrusion, industrial furnaces, heat-treatment systems, automated production lines, food processing equipment, and other high-demand environments where stable and accurate temperature regulation is essential.

Core Advantages of the C Series

✔ High-Precision PID + Self-Tuning

Equipped with a 16-bit microprocessor, the C Series delivers fast, stable PID response.Self-tuning functionality automatically adjusts PID parameters to suit real-world load and process conditions.

✔ Wide Input Compatibility for Greater Flexibility

- Thermocouples: J / K / T

- RTD: Pt100

- Analog inputs: 0–10V / 4–20mA (suitable for remote SV setting)

✔ Multiple Output Options for Different Load Types

- Relay output

- SSR drive pulse

- Linear analog output (0–10V / 4–20mA)

Capable of driving:

- SSR

- SCR

- Contactors

- Motorized valves

- Suitable for a wide range of heating mechanisms and industrial applications.

✔ Dual Output for Heating / Cooling PID Control

Ideal for applications requiring temperature stabilization through both heating and forced cooling, such as:- Industrial furnaces

- Temperature-controlled reactors

- Mold temperature units

- Food processing and thermal systems

One controller handles both directions.

✔ Programmable Temperature Profiles (Up to 16 Steps)

Easily configure multi-stage temperature ramps and soak periods.Perfect for:

- Heat-treatment cycles

- Curing and vulcanization

- Controlled heating/cooling sequences

- Automated process temperature management

Advanced Features of the C Series

- High-performance 16-bit MCU

- PID + Self-Tuning

- Multi-input support (TC / RTD / Analog)

- Multi-output support (Relay / SSR / Analog)

- Forward / Reverse action (Heating / Cooling)

- Dual-output models for bi-directional PID control

- 26 alarm modes with sensor break detection (HBA)

- Retransmission output (PV or MV) for PLCs or recorders

- Manual / Auto output switching

- Modbus RTU & ASCII communication up to 38,400 bps

- 16-step programmable control with repeat settings

This makes the C Series an ideal choice for equipment manufacturers requiring high flexibility and integration capability.

Industries and Applications

Plastics & Rubber Processing

- Injection molding machines (including PID control for nozzles or hot runners)

- Extrusion machines

- Barrel heater control

- Mold heating and cooling systems

Industrial Heating Equipment

- Industrial ovens

- Furnaces and kilns

- Heat-treatment systems (annealing, curing, sintering)

- Hot-plate forming machines

- Vacuum furnaces

Food Processing & Automation

- Steam heating systems

- Fermentation tanks

- Thermal reactors

- High-temperature sterilization systems

Typical Temperature Control Functions

- Heater band temperature control

- Mold temperature control (with cooling)

- Hot-runner / nozzle heating

- Uniform hot-plate temperature regulation

- Heat-sealing knife / sealing-line temperature control

- Industrial temperature ramp/soak control

C Series Model Specifications and Selection Guide

| Model | Panel Size | Weight | Key Features | Recommended Applications |

| C100 | 48×48 mm | 200 g | Basic PID, single output | Small equipment, single heating zone |

| C200 | 48×96 mm | 340 g | Single/dual output, PID | Medium-size equipment, larger display |

| C300 | 72×72 mm | 280 g | Dual output, program control | Multi-zone control |

| C400 | 96×96 mm | 360 g | High-end PID, 16-step program | Mid-to-large industrial systems |

| C500 | 96×96 mm | 360 g | Maximum I/O + full communication | PLC / automation integration |

C Series vs. A Series — Feature Comparison

| Comparison Item | A Series (General Control) | C Series (Advanced PID / Program Control) |

| Control Method | ON/OFF / Basic | PID + Self-Tuning |

| Program Control | ✘ | ✔ Up to 16 steps |

| Input Support | Thermocouple | Thermocouple / RTD / Analog |

| Dual Output Heat/Cool | ✘ | ✔ |

| Communication | Limited / None | Modbus RTU / ASCII |

| Application Level | Basic heating control | Precision control & automation |

| Best For | Entry-level machines | Mid- to high-end industrial equipment |

Frequently Asked Questions (FAQ)

Q1: What is the main difference between the C Series and the A Series?

The C Series is designed for advanced applications requiring PID control, program segments, dual output, and communication.The A Series is intended for general-purpose heating control.Q2: Does the C Series support RTD or analog inputs?

Yes. It supports Pt100 RTD and 0–10V / 4–20mA analog inputs.Q3: Can it drive SSR or SCR power modules?

Yes. The C Series offers pulse and analog outputs suitable for SSR and SCR control.Q4: Does it support PLC / HMI communication?

Yes. Modbus RTU / ASCII is available for system integration.Q5: Can it be used for temperature ramp/soak or multi-stage heating?

Yes. The 16-step program function supports multi-stage temperature profiles.Q6: Is OEM customization available?

Yes. ARICO provides OEM/ODM services including I/O configuration, housing design, panel labeling, and firmware parameter customization.| Model | C100 | C200 | C300 | C400 | C500 | |

|

Dimension W × H Unit:mm |

W48×H48 | W48×H96 | W72×H72 | W96×H96 | W96×H48 | |

| Unit Weight | 130g | 200g | 200g | 280g | 200g | |

| Display Type |

4 digital high brightness and red color 4 digital high brightness and green color |

|||||

| Power Consumption | 4W | 5W | 4W | |||

| Power Supply | AC90~240V(60/50Hz), DC24V(Optional) | |||||

| Storage / Operate | 0~65°C/0~50°C;20~90% RH | |||||

| Data Backup Memory | EEPROM, 10 years | |||||

| Accuracy | 0.3 % Full scale | |||||

| Alarm Output | Relay contact 8A, 250VAC | |||||

| Controlling Measure | ON / OFF, P, PI, PD, PID | |||||

| Approved Standard | CE-T160811N10-E | |||||

| Controlling Output | ||||||

| Relay contact | AC250V/8A | |||||

| Digital Voltage | DC24V/20mA(MAX) | |||||

| Analog Voltage | 0~10V (Input Impedance: 1KΩ Max.) | |||||

| Analog Current | 4 ~20mA (Input Impedance: 600Ω Max.) | |||||

| Input Type | ||||||

| Thermocouple |

J, K, R, S, B, E, N, T, W3, W5, PL-II (Input Impedance: approx. 1KΩ Max.) |

|||||

| RTD | PT-100 (DIN), JPT-100 (JIS) | |||||

| Linear Analog | 0~10mV, 0~20mV, 0~50mV, 4~20mA, 0~10V....see operating instructions | |||||